Company producing Johnson & Johnson COVID-19 vaccine had history of violations

The company at the center of quality problems that led Johnson & Johnson to discard an unknown amount of its COVID-19 vaccine has a string of citations from U.S. health officials for quality-control problems.

Emergent BioSolutions, a little-known company at the center of the vaccine supply chain, was a key to Johnson & Johnson’s plan to deliver 100 million doses of its vaccine to the U.S. by the end of May. But the company has been cited repeatedly by the Food and Drug Administration for problems such as poorly trained employees, cracked vials and mold at one of its facilities, according to records obtained by the Associated Press through the Freedom of Information Act.

The records cover inspections at Emergent facilities since 2017.

Johnson & Johnson said Wednesday that a batch of vaccine made by Emergent at its Baltimore factory, known as Bayview, couldn’t be used because it didn’t meet quality standards. It was unclear how many doses were involved or how the problem would affect future deliveries of Johnson & Johnson’s vaccine. The company said in a statement that it was still planning to deliver 100 million doses by the end of June and was “aiming to deliver those doses by the end of May.”

Johnson & Johnson linked up with Emergent in April 2020, enlisting the lesser-known company to manufacture the COVID-19 vaccine that Johnson & Johnson was developing with federal funding. At the time, Emergent’s Bayview facility wasn’t scaled for making millions of doses of a potential COVID-19 vaccine, according to the FDA records, which describe the plant as a contract testing laboratory that “did not manufacture products for distribution.” Upgrades in technology and personnel were required before Bayview could begin making what’s known as “drug substance” material for the vaccine, a two-month process during which the required biological cells are grown.

The FDA inspected Emergent’s Bayview plant in April 2020, just as the agreement with Johnson & Johnson was being announced. The agency criticized the company for problems with its testing of a potential treatment for anthrax, according to the records obtained by the AP. The FDA’s lead investigator cited the company for failing to train employees “in the particular operations they perform as part of their function and current good manufacturing practices.”

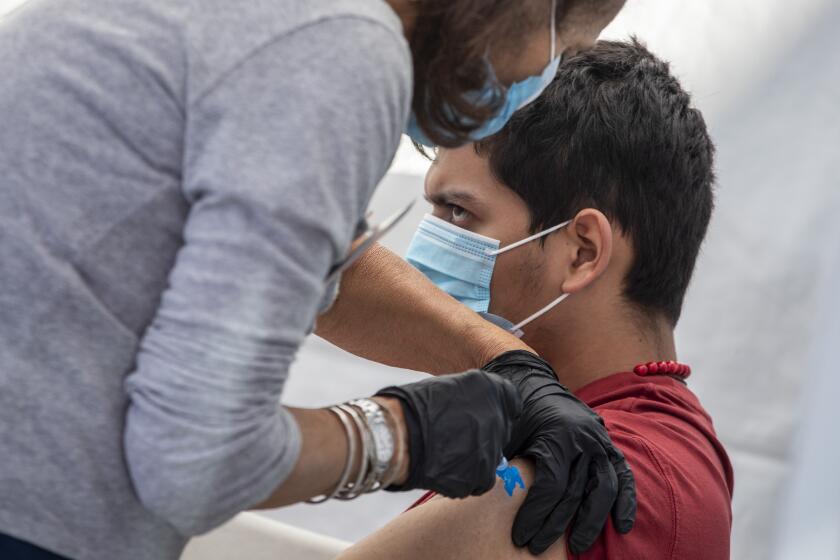

Five of the state’s top doctors get the Johnson & Johnson vaccine in front of news cameras as officials seek to promote the most recently approved shot.

On the same day, Johnson & Johnson, in a separate news release, heralded its partnership with Emergent as a step toward the pharmaceutical giant’s goal of supplying more than 1 billion doses of its vaccine globally by the end of 2021.

Other problems cited by the FDA during the April 2020 inspection included failures by the Bayview plant to ensure that electronic data generated through testing of drug ingredients “was protected from deletion or manipulation.” A closer review found 202 deletions and 543 reprocessed files, yet the company had not investigated how those alterations had occurred or their possible effects, according to the records. The FDA’s lead investigator, Marcellinus Dordunoo, wrote that Emergent had not investigated what he described as “data integrity concerns.”

Emergent also did not follow proper testing and lab procedures at Bayview, the FDA said, noting that “deviations from test methods are not investigated, and are manually corrected days after performance, with no supporting data or documented justification.”

Reaching that milestone “would dramatically change the trajectory of the pandemic,” Public Health Director Barbara Ferrer said

The FDA also criticized Emergent for carelessness in the handling of rejected materials in the Bayview plant. An inspector observed items in a “reject cage” that did not have reject labels and wrote that “separate or defined areas to prevent contamination or mix-ups are deficient.”

The inspection was the most recent in a series of critical reports from the FDA about Emergent, including one following a December 2017 inspection at a plant in Canton, Mass., in which the FDA said the company hadn’t corrected “continued low level mold and yeast isolates” found in the facility.

Nearly a year later, agency investigators questioned why Emergent had “an unwritten policy of not conducting routine compliance audits” at a separate plant in Baltimore, known as Camden, where an anthrax vaccine is put into vials.

FDA inspectors noted that the company’s processes there were flawed. “Your firm received 3 complaints for residue on the outside of the vials for 3 different lots,” the FDA’s inspection report said. Tests on that residue confirmed it was vaccine, according to the report.

The agency, in another 2018 inspection, noted Emergent’s ongoing problems managing contamination at the Baltimore facility where BioThrax is produced: “Procedures designed to prevent microbiological contamination of drug products purporting to be sterile are not adequately established and followed.” The FDA’s inspectors also noted that Emergent staff filling vials of vaccine held “their hands directly above open vials” in a way that violated sterility safeguards.

The FDA declined repeated requests to discuss the inspections at Emergent’s facilities. A spokesman said the agency “cannot comment on any particular company or any potential or ongoing compliance matters.”

Emergent’s revenues skyrocketed during the Trump administration, jumping from about $523 million in 2015 to more than $1.5 billion in 2020. The company has invested heavily in lobbying the federal government, according to disclosure records, which show the company spent $3.6 million on lobbying in 2020 alone.

A major increase in the supply of the Johnson & Johnson COVID-19 vaccine allows states — including California — to expand eligibility for shots.

Emergent is one of about 10 companies that Johnson & Johnson is using to speed up manufacturing of its recently authorized vaccine, the company said. The Bayview factory where the tainted vaccine ingredient was found had not yet been cleared by the FDA, so no vaccine in circulation is affected.

Emergent declined to comment.

President Biden has pledged to have enough vaccines for all adults in the U.S. by the end of May. The federal government has ordered enough two-dose shots from Pfizer and Moderna to vaccinate 200 million people, which should be delivered by late May, plus the 100 million single-dose shots from Johnson & Johnson.

A federal official said Wednesday evening that the administration’s goal could be met without additional Johnson & Johnson doses.

All three COVID-19 vaccines available in the U.S. have pros and cons. And all are essential to stopping the pandemic.

A Johnson & Johnson spokesman said earlier Wednesday that the company met the end-of-March goal, and the Centers for Disease Control and Prevention’s online vaccine tracker showed that Johnson & Johnson had provided about 6.8 million doses to the U.S. vaccine effort. Johnson & Johnson has been shipping finished vaccines from its factory in the Netherlands to the U.S.

Johnson & Johnson said it was putting more of its manufacturing and quality experts inside Emergent’s factory to supervise production of the COVID-19 vaccine, a move meant to enable delivery of an additional 24 million vaccine doses through April.

Johnson & Johnson said it still expects to deliver more than 1 billion vaccine doses globally by the end of the year.

More to Read

Sign up for Essential California

The most important California stories and recommendations in your inbox every morning.

You may occasionally receive promotional content from the Los Angeles Times.